1. Product Overview

High – Temperature Viscosity – Increasing and Filtrate – Reducing Agent Type II (HTR240) is an advanced additive meticulously developed by Beijing Sanherunjing Technology Co., Ltd. for drilling fluid systems. This product is designed to address the challenges posed by high – temperature drilling environments. It comes in a 25 – kilogram package and is presented as a powder – like substance.

2.Functions and Characteristics

Product Features and Advantages

- Exceptional High – Temperature Resistance: HTR240 can withstand temperatures up to 240°C, ensuring stable performance in extremely high – heat conditions, which is crucial for deep – well and high – temperature drilling operations.

- Outstanding Compatibility: It shows excellent compatibility with various components in drilling fluids, including different types of base fluids and other additives. This allows for easy integration into existing drilling fluid formulations without causing any compatibility issues.

- Enhanced Performance Stability: The product maintains its effectiveness over a wide range of drilling fluid properties and operating conditions. It is less affected by changes in pH, salinity, and other environmental factors, providing consistent performance throughout the drilling process.

- Environmentally Friendly: Manufactured with eco – friendly materials, HTR240 minimizes its environmental impact during drilling operations, helping drilling companies meet environmental protection requirements.

Main Functions

- Viscosity Enhancement: Significantly increases the viscosity of drilling fluids. This increased viscosity improves the fluid’s ability to suspend and carry drill cuttings, preventing cuttings from settling at the bottom of the wellbore and ensuring smooth drilling progress.

- Shear – Thinning and Shear – Thickening Regulation: Exhibits precise shear – thinning and shear – thickening properties. During circulation, it reduces the pumping pressure by thinning under shear force, and when the fluid is at rest, it thickens to hold the cuttings in suspension.

- Filtrate Loss Reduction: Effectively reduces the filtrate loss of drilling fluids. By forming a dense filter cake on the wellbore wall, it prevents the invasion of formation fluids into the wellbore, protecting the formation from damage and maintaining wellbore stability.

Application Scenarios

- Ultra – Deep – Well Drilling: In ultra – deep – well projects where extremely high temperatures are encountered, HTR240 is an ideal choice. It can be added to both water – based and oil – based drilling fluids to ensure that the fluid properties remain stable under high – temperature and high – pressure conditions.

- Geothermal Drilling: Geothermal drilling often involves high – temperature formations. HTR240 can be used to formulate drilling fluids that can withstand the high – temperature environment, enabling efficient drilling and wellbore protection in geothermal projects.

3.Technical Specifications

Recommended Dosage

The recommended dosage of HTR240 may vary depending on the specific requirements of the drilling fluid system, such as the type of base fluid, the characteristics of the formation being drilled, and the desired fluid properties. Generally:

- For water – based drilling fluids, the recommended dosage is 0.3% – 0.8%.

- For oil – based drilling fluids, the recommended dosage is 0.5% – 1.0%.It is advisable to conduct laboratory tests or field trials to determine the optimal dosage for specific drilling operations.

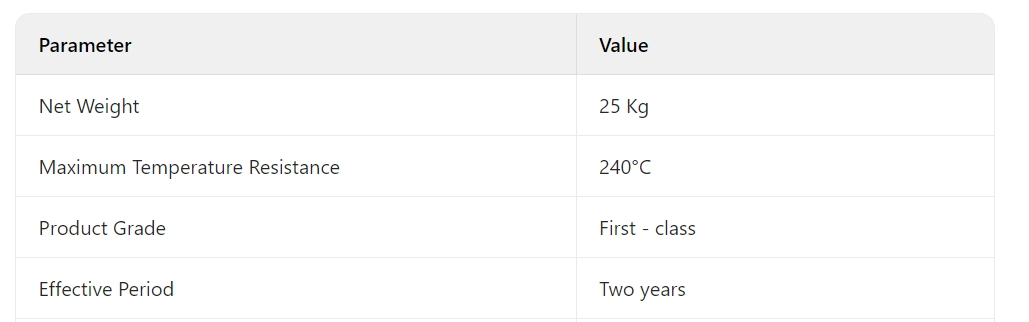

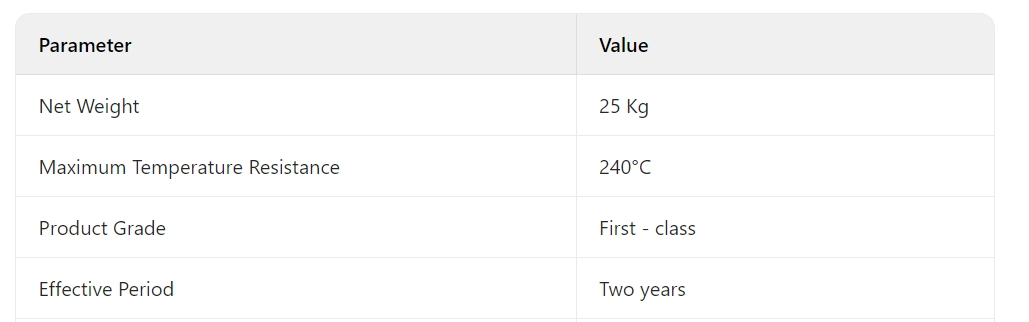

. Product Parameter Table

4.Packaging & Storage

Packaging: 25 kg triple-layer kraft bags

Storage Conditions:

Keep dry and protect from direct sunlight and moisture.

Validity Period: 24 months from production date (see batch code for details).

Additional Details:

Versatile Application: The product adaptability allows it to be tailored for different drilling scenarios, ensuring optimal performance and cost-effectiveness.

Disclaimer: The above information is provided for reference only. Actual performance may vary based on specific drilling conditions and operational practices. Please consult with technical experts for detailed application guidance.

.jpg&w=440;&h=440;&zc=1)

2.jpg&w=440;&h=440;&zc=1)

.jpg&w=80;&h=80;&zc=1)

2.jpg&w=80;&h=80;&zc=1)

2.jpg)