1.Product Introduction

High – Temperature Viscosity – Increasing and Filtrate – Reducing Agent (HTR180) is a copolymer synthesized through the polymerization of acrylic acid, acrylamide, a new type of cationic cyclic monomer, etc. It is used as a high – temperature – resistant filtrate – reducing agent for fresh – water and salt – water drilling fluids. The product appears as a white or light – yellow powder.

Product Features and Advantages

- High – Temperature Resistance: It can withstand temperatures up to 180°C, ensuring stable performance in high – heat environments commonly encountered in deep – well drilling.

- Excellent Compatibility: Readily compatible with a wide range of drilling fluid components, allowing for seamless integration into existing drilling fluid systems without causing adverse reactions.

- Environmental Friendliness: Manufactured with environmentally responsible materials, minimizing the impact on the environment during drilling operations.

2. Functions and Characteristics

- It has excellent filtrate – reducing performance, as well as certain effects of increasing viscosity and shear force.

- It has strong salt – resistance up to saturation and strong resistance to calcium and magnesium ions, and can be used to prepare various water – based drilling fluid systems such as salt – water and seawater drilling fluids.

- It has good thermal stability and can resist temperatures up to 180°C.

- Viscosity Increase: Significantly enhances the viscosity of drilling fluids, improving the fluid’s ability to carry cuttings and maintain wellbore stability.

- Shear – Thinning Property: Exhibits excellent shear – thinning characteristics, reducing pumping resistance during circulation while still providing sufficient viscosity to suspend cuttings when the fluid is at rest.

- Filtrate Reduction: Effectively reduces the filtrate loss of drilling fluids, preventing the invasion of formation fluids into the wellbore and protecting the formation from damage.

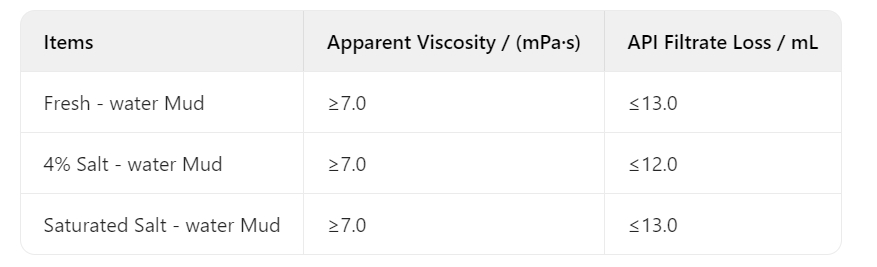

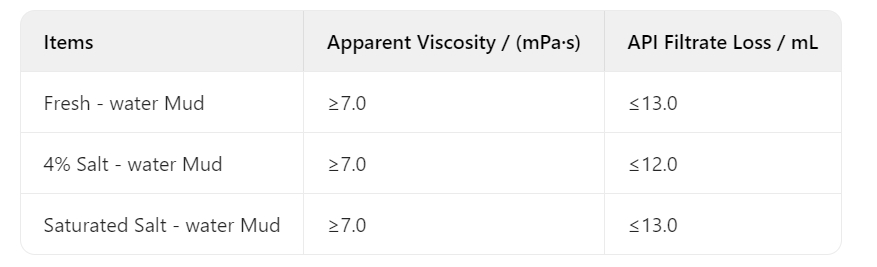

3.Technical Indicators

4.Application Scope

It can be widely used in fresh – water, salt – water, and seawater drilling fluid systems.

- Deep – Well Drilling: Ideal for deep – well operations where high temperatures are prevalent. It can be added to water – based or oil – based drilling fluids to maintain fluid performance under extreme conditions.

- Complex Formation Drilling: In formations with high permeability or where wellbore stability is a concern, HTR180 helps to control filtrate loss and improve the carrying capacity of the drilling fluid, ensuring smooth drilling progress.

The recommended dosage may vary depending on the specific requirements of the drilling fluid system and the formation characteristics. Generally, it is advisable to conduct field tests to determine the optimal dosage.

5. Recommended Dosage

- Recommended dosage for fresh – water drilling fluids: 0.1 – 0.3%.

- Recommended dosage for salt – water or seawater drilling fluids: 0.5 – 1.0%.

- The actual dosage of the treatment agent may vary according to the use environment.

6.Packaging & Storage

Packaging: 25 kg triple-layer kraft bags

Storage Conditions:

Keep dry and protect from direct sunlight and moisture.

Validity Period: 24 months from production date (see batch code for details).

Additional Details:

Versatile Application: The product adaptability allows it to be tailored for different drilling scenarios, ensuring optimal performance and cost-effectiveness.

Disclaimer: The above information is provided for reference only. Actual performance may vary based on specific drilling conditions and operational practices. Please consult with technical experts for detailed application guidance.

.jpg&w=440;&h=440;&zc=1)

.jpg&w=440;&h=440;&zc=1)

.jpg&w=80;&h=80;&zc=1)

.jpg&w=80;&h=80;&zc=1)

.jpg)